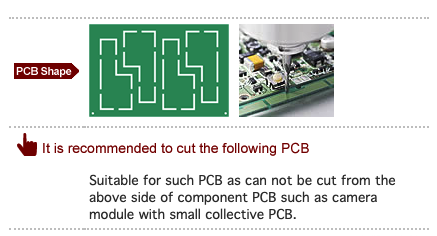

Select a machine by PCB shape

SAM-CT22ZR IN-LINE

Able to cut tall packaging PCB By downside cutting

Feature

-

1

Cutting with Jig circulation system is done and this is suitable for PCB with a plenty of pieces.

-

2

Complete automation process from Magazine to supply, cutting and storing in tray of PCB.

-

3

Cutting dusts are reduced as much as possible by brush and ionizer unit in each part.

-

4

Nozzle suction and brush suction are adopted at cutting unit and the function to reduce cutting dust is adopted.

-

5

Cutting can be done without stress on PCB by using Spindle with high performance.

-

6

Switch of product model can easily be done by operation of Touch Panel and replacement of Jig.

-

7

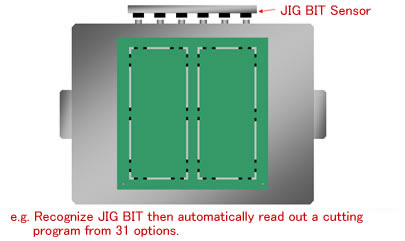

Automatic select cutting program with JIG BIT system.

Basic Specifications

| PCB | Size(Max.):60×200mm Angle:0.4-2.0mm Material(Resin):FR4, CEM1, CEM3 etc. |

|---|---|

| JIG Carrier Unit | P&P X Driving:AC Servo P&P Z Driving:Twin Head Cylinder JIG Positioning:Positioning Pin Type JIG Clamp:Chuck Cylinder |

| Cutting Unit | Operation Panel:Touch Panel Cutting Speed:50mm/sec Repeatability:±0.01mm Movement Speed(Max.):600mm/sec X.Y.Z Driving:Servo PRG Data Creation:Direct, Coordinate Input Teaching (PRG Edit Software) |

| Spindle Unit | Collet Dia.:φ3.175mm Router Bit Dia.:φ0.8, φ1.0, φ1.2, φ1.5, φ2.0mm Router Bit Replacement:Air Chuck Driving:High Frequency Induction Motor Rotation:5,000-50,000rpm |

| Loading Unit | PCB Magazine Rack Dimension:L200×W67×H140mm PCB Magazine Rack Store No.:8 pcs PCB Stock No.:20 sheets/Magazine Feeding:Conveyer &Retracting Cylinder (PCB Clamp) |

| Unloading Unit | Operation Panel:Operation Panel Movement Speed(Max.):1,000mm/sec X,Y Axes Control:PLC Z Axis:Twin Head Cylinder Q axis:270°Motor Driving Repeatability:±0.01mm Tray Stock Sheet No.:30 pcs PCB Magazine Rack Dimension:135.8×315.8×11.7mm |

| Utility | Power:φ3 AC200V 50/60Hz Air Pressure:0.5MPa Power Consumption:5.0KVA (Inc.Dust Collector) Dimension:L2700×D1250×H1400mm Weight:Approx.1500kg |

-

Inquiry About Product

INQUIRY -

Technology and Support

SUPPORT SYSTEM