Select an In-line machine

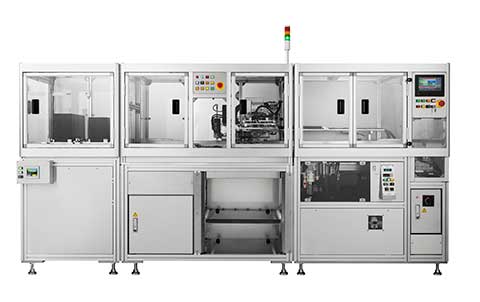

SAM-CT23ZLi

In-line model with excellent dust collection and space saving

Feature

-

1

Apply underside cutting method. This type machine suitable for cutting mounted PCB which hard to cut from upper side.

-

2

Special cutting result that low-stress, hi-accuracy, hi-quality with router bit.

-

3

Safely cut PCB even with overlap connector.

-

4

Efficient and effective structure have function like pinpoint absorb slush powder from underside.

-

5

Near zero slush powder attach on parts such as connector.

-

6

Hold-structure prevents shock during cutting.

-

7

Various safety sensors are included as standard (area sensor/work detection/work float detection/router bit broken/router bit drop).

-

8

Compact dust collector with low-noise (approx.65dB[A]).Realized small-footprint.

Basic Specifications

| Size | 1600㎜×900㎜×1500㎜(500kg) |

|---|---|

| PCB Size(Max.) | 250×350 |

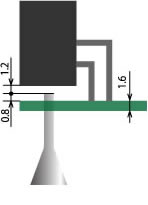

| PCB Thickness | 0.8~2.0mm |

| PCB Material(Resin) | FR4, CEM1, CEM3 Resin etc. |

| Router bit diameter | 0.8mm~2.0mm |

| Cutting Speed(Max.) | 50mm/sec |

| Moving Speed(Max.) | 500mm/sec(X/Y axis) |

| Repeat Accuracy | ±0.01mm |

| Z Axis Stroke(Max.) | 50mm |

| Spindle Spec. | 25,000~50,000rpm |

| X,Y,Z Axes Control | AC Servo Motor(X/Y axis)Cylinder(Z axis) |

| Power Voltage | 200V 50/60Hz |

| Power Consumption | 3.0KVA |

-

Inquiry About Product

INQUIRY -

Technology and Support

SUPPORT SYSTEM