Feature

-

1

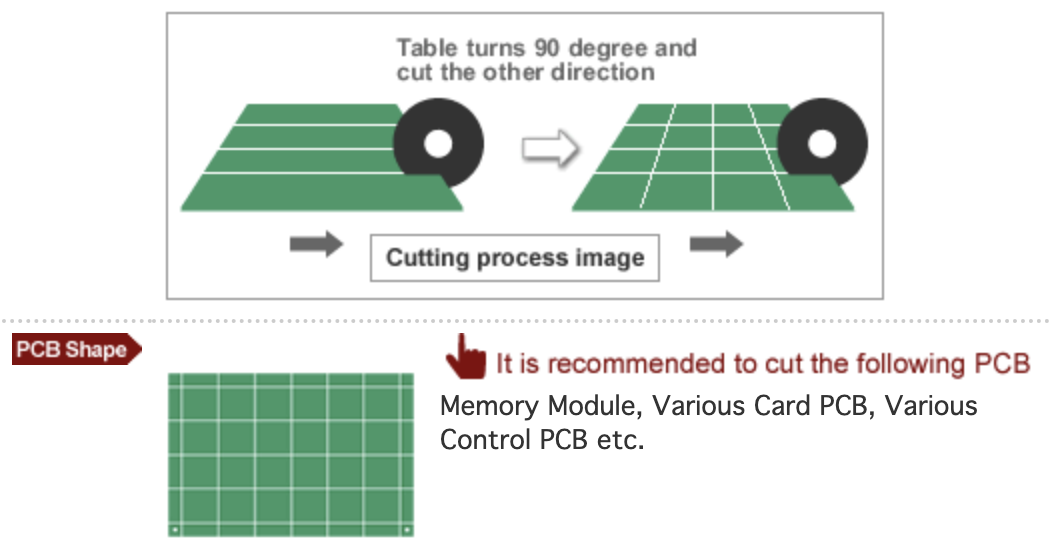

High Accuracy and High Speed Cutting is realized because of Dicing Type Cutting. (1 – 200mm/sec)

-

2

Functions such as Image Processing, Damage/Wear Confirmation for Blade are installed as standard ones.

-

3

Safety is increased during Feeding PCB by using Jig Pallet at Cutting Unit.

-

4

Cutting dusts are recovered inside Jig Pallet Cleaning Structure installed every time.

-

5

Automatic Removal Structure of Discarded PCB is installed as standard equipment at Return Conveyor Unit.

-

6

Confirmation Structure to prevent mistakes for PCB setting with adsorption at Jig Pallet Unit is installed as standard equipment.

Basic Specifications

| PCB | Max.250mm×330mm |

|---|---|

| Thickness | Max.2mm |

| Carry-in Conveyor Unit | Conveyor:Round Belt PCB Clamp:Cylinder Chucking Unit PCB Feeding:Single Axis Rodless Cylinder |

| Cutting Unit X Axis | Moving Range:520mm Moving Speed:500mm/sec Repeat Accuracy:±0.01mm Scale Resolution:0.001mm |

| Cutting Unit Y Axis | Moving Range:465mm Moving Speed:1 - 200mm/sec Repeat Accuracy:±0.01mm Scale Resolution:0.001mm |

| Cutting Unit Z Axis | Moving Range:27mm Moving Speed:1 - 50mm/sec Repeat Accuracy:±0.01mm Scale Resolution:0.001mm |

| Cutting Unit θAxis | Motor:DD motor Max. Rotation Angle:100° Repeat Accuracy:±3" |

| Spindle Unit | Motor:AC Induction Motor Rated Output:90W |

| Blade | Outer diameter×Inner diameter:φ75×40mm Thickness:0.1 - 0.5mm |

| Unloading P&P | Jig Pallet Feeding:Cylinder Chucking Unit (Single Rodless Cylinder) |

| Return C/V Unit | Conbeyor:Round Beolt Discarded PCB Removal:Cylinder P&P (Vacuum Pad) Cleaning:Rotating Brush (wool) |

| Jig Pallet | Dimention:W390×D220×T10mm Sheet No.(standard):3 |

| Power | 4KVA |

| Air Supply Pressure | 0.5 - 0.7Mpa |

| Air Consumption | 500L/min (A.N.R) |

| Machine Dimention (incl.Return C/V Unit) |

W2400×D1750×H1570mm |

| Machine Weight (incl.Return C/V Unit) |

Approx.1200kg |

-

Inquiry About Product

INQUIRY -

Technology and Support

SUPPORT SYSTEM