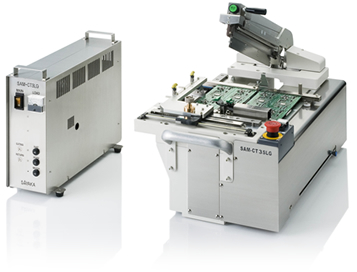

SAM-CT3SLG

Hole card of low cost manual slicer for test cutting and high-mix low-volume production

Feature

-

1

Compact desktop design is perfect for cell production.

-

2

Achieved a low price by manual positioning. Support mass production by lettering guide.

-

3

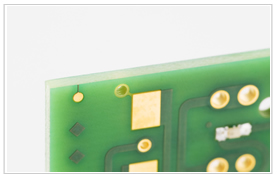

Use blade to cut PCB like grinding process, get smooth finish of PCB cross section with low stress.

-

4

Attached holding mechanism which has dust collection function, reduce PCB vibration during cutting and also collect dust effectively.

-

5

Reduce PCB production cost and also prevent PCB warpage, because v-groove free.

-

6

Blade standard thickness is 0.3mm, it is best for both PCB with or without V-groove.

-

7

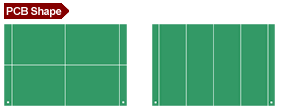

Need no pallet(fixture) to cut PCB because it use width adjustable mechanical chuck.

(*In case need pallet it depends on the PCB shapes)

-

8

Max.300mm/s cutting speed available for paper phenol PCB when you using newly developed tip saw. And also support Alu PCB cutting.

Basic Specifications

| PCB | Y:Cutting Range(Max.):330mm X:Cutting Range(Max.):196mm(STD) 296mm(OPT) Material(Resin):FR4, CEM1, CEM3 etc. Components Height(Max.):47mm from PCCB upper surface,10mm from underside surface |

|---|---|

| Main Axis | Type of Motor:Type of Motor 100W Main Axis Rotation:2,000-7,000rpm |

| Main Axis Movement |

Type of Motor:DC Motor Movement Speed:70-150mm/s Cutting Speed:20-100mm/s |

| Blade | Blade(GC Blade):OD=125mm,ID=40mm,t=0.2-0.5mm,0.3(STD) PCB Holding:Cut with holding mechanical chuck and slide rail |

| Main Unit Utility | Power Voltage:φ1,AC100V、50/60Hz Power Consumption(Max.):Approx.300VA(dust collector is count outed) Dimension(Controller BOX Dimension):W463×D779×H352mm (when chuck is stored) (W170×D420×H363.5mm) Net Weight:Approx.50kg |

| Dust Collector | Power:φ1, AC100V, 50/60Hz, 1.0KVA |

-

Inquiry About Product

INQUIRY -

Technology and Support

SUPPORT SYSTEM